LCD Resin Instructions for Use

- Dental Resins

- Jewelry Resins

- FAQs

-

Profile Settings for 3D Printers

Anycubic 3D Printers Settings Phrozen 3D Printers Settings Elegoo 3D Printers Settings Flashforge 3D Printers Settings Wanhao 3D Printers Settings Epax 3D Printers Settings Longer 3D Printers Settings Creality 3D Printers Settings Nova3D Printers Settings Peoply 3D Printers Settings Zortrax 3D Printers Settings

- Digital Jewelry Production

- Digital Dental Production

- Blog

Table of Contents

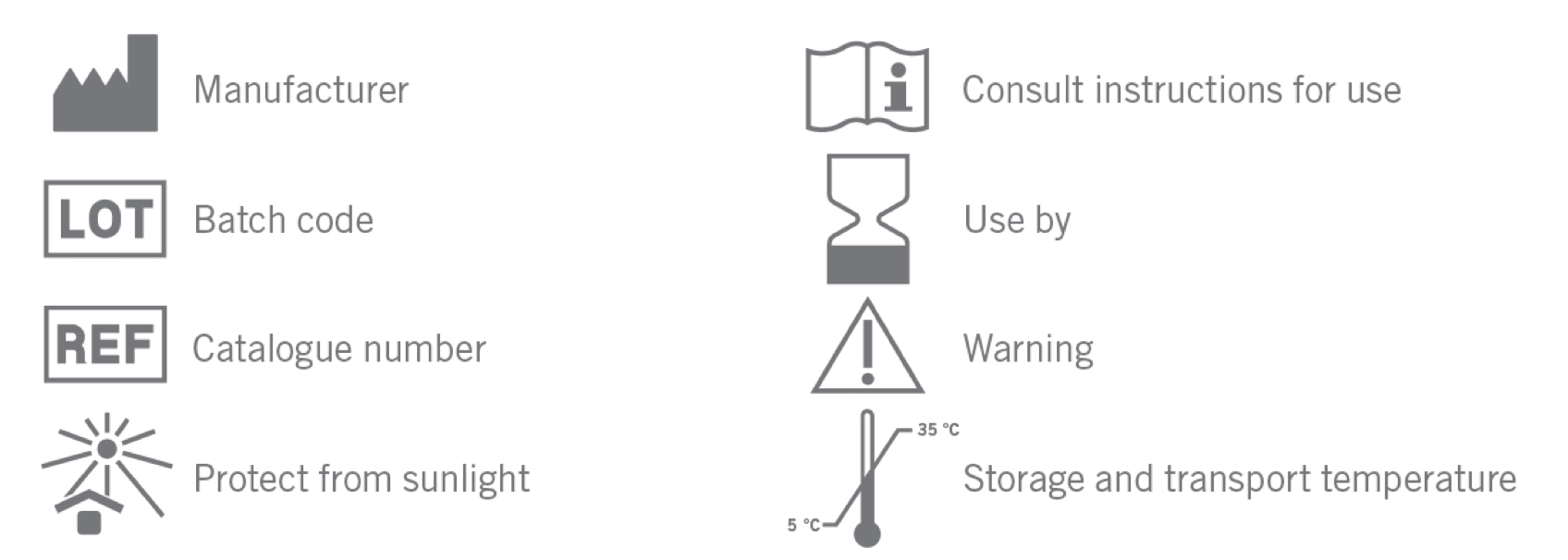

LCD Resin Instructions for Use

1- Indented Use

LCD Resin is a jewelry resin developed for compatibility with LCD devices. LCD resin shows superior casting quality. LCD Resin is compatible with either 385 or 405 nm 3D printer devices.

2- Contraindications

Power Resins LCD Resin should not be used for any purpose other than just jewelry applications. Any deviation from this instruction for use may adversely affect the chemical and physical quality of the 3D product. In case of an allergic reaction, please consult a medical doctor.

3- Safety Instructions

To ensure optimum further processing, please carefully read the information contained in the instructions for use. Misuse and failure to observe information can have a detrimental effect on quality. When working with resin, nitrile gloves, goggles, and a jacket should be worn as a means of protection.

The safety instructions and precautions outlined in the LCD Resin operating instructions and safety data sheet will apply to the removal of liquid resin and uncured resin.

4- Side Effects and Precautions

In liquid form;

Inhalation

Irritates the respiratory organs. High concentrations can lead to irritation of the respiratory passages, dizziness, headaches, and loss of consciousness.

Skin contact

Sensitization or irritation is possible from contact with the skin. Repeated and/or extended skin contact can cause inflammations.

Eye contact

High air concentrations can lead to eye irritations. If on eye wash with plenty of water. Remove your contact lenses. If skin irritation or rash occurs: Get medical advice/attention

Swallowing

Low oral toxicity; ingestion can, however, lead to irritation of the gastrointestinal tract.

Power Resins Dental Model LT Resin

Hazardous Component: Phenylbis (2,4,6-trimethyl benzoyl)-phosphine oxide

| Color | Translucent Green |

| Viscosity | 490 – 510 mPa.s |

| Density | 1.1 g/cm3 |

Warning!

In liquid form;

P280 Wear protective gloves, glass, and clothing while using. Advised to use nitryl gloves.

H319 May cause eye irritation.

P305+P351+P338 If on eye wash with plenty of water. Remove your contact lenses. If skin irritation or rash occurs: Get medical advice/attention

Light sensitive! Keep open containers away from direct sunlight or room light.

Keep out of reach of children.

Keep away from food.

Safety instructions as per MSDS

• Avoid inhaling aerosol

• Wear protective gloves/eye protection

• Call a doctor/physician if you feel unwell

• If skin irritation/rash occurs: get medical advice/attention

• If eye irritation persists: get medical advice/attention

• Dispose of contents / container as per local and national regulations

5- General Information on Handling

Delivery

Power Resins LCD Resin is supplied in light-tight, sealed bottles.

Please check the following points on receipt of the goods:

• Integrity of the bottle/pack

• Quantity

• Color

• Shipping documents and designation

Storage Conditions

Keep the resin bottle range of 22-27 OC / 71-80 OF. The minimum shelf life date printed on the product must be observed. Store this product in tightly closed containers in a properly vented storage area under dry conditions away from sparks and open flames. Avoid the material to direct sunlight.

Shelf life is 6 months from production. Perfect processing cannot be guaranteed if materials that have exceeded their minimum shelf life date are used. For additional information, please see Material Safety Data Sheet.

6- Processing

Processing

Power Resins LCD Resin is designed to work with all LCD 3D printers. See the %% section on powerresins.com for optimization databases.

Cleaning:

a. Allow the model to clean for 3 minutes in compartment 1 of the MEDIFIVE washer containing ethanol solution (96%). After the process is complete, dry the model with a spray air gun.

b. Allow the model washed and dried in compartment 1 to be cleaned in compartment 2 of the MEDIFIVE washer containing ethanol solution (96%) for 3 minutes. After the process is complete, dry the model with a spray air gun.

Do not exceed the 6-minute total cleaning procedure as this may cause deterioration of printed objects.

Hint: Resin residues can also be removed using a brush moistened with ethanol (96%).

Finishing:

The completely cleaned print objects must be post-cured to attain the required material properties and biocompatibility.

7- Post-Curing

Caution: Post-curing outside of the recommended settings can lead to suboptimal mechanical and biocompatibility properties. Post-cure only in accordance with official recommendations from Power Resins for the best possible results.

Recommended post-curing

2x2000 flash on Otoflash G-171 curing device

30 minutes in a MEDIFIVE curing room at 3rd-degree light intensity

The mechanical values to be obtained when the recommended post processes are applied are given in the table below.

| Wavelength | 405 nm |

| Flexural strength | >21 MPa |

| Flexural modulus | 472 MPa |

8- Shrinkage

Prints taken from 3D printers show shrinkage of approximately 1% by weight at room temperature (20 - 22 °C (68 - 72 °F) within 1 hour after washing with alcohol and drying.

9- Recommended Burnout Cycle

Power Resins suggestion for the casting process consists of three sections.

1. The cleaning part;

the sample rings I sent you are already cleaned.

2. Investment process part;

We suggest Ransom&Randolph Plasticast for investment powder. It is optional, you can use what you have at the moment.

Adding boric acid and calcium nitrate to the investment solutions; is optional. Our tests show us that with these supplements, the casting quality has improved.

Hot water bath; also optional. Again, this step helps for better casting results.

3. Burnout process part;

please use option 2 in the earlier email. As it follows;

Set the furnace temperature to 150⁰C.

Load the flask into the furnace with its face downwards at 150⁰C temperature.

Hold for 3 hours at 150⁰C

Ramp to 550⁰C in 30 minutes.

Hold at 550⁰C for 4 hours.

Ramp to 600⁰C in 30 minutes.

Hold at 600⁰C for 30 minutes.

Ramp to 650⁰C in 30 minutes.

Hold at 650⁰C for 30 minutes.

Ramp to 700⁰C in 30 minutes.

Hold at 700⁰C for 30 minutes.

Ramp to 750⁰C in 30 minutes.

Hold at 750⁰C for 30 minutes.

Ramp to 600⁰C in 1 hour.

Hold at 600⁰C for 1 hour.

Remove the flask from the furnace and blow it with compressed air thoroughly then reload it back in the furnace with its face upwards for gases to escape for 1 hour at 600⁰C.

Cast the flask.

Blowing compressed air through the flask is very important. In fact, you can open the furnace hatch during the burnout process a couple of times for the oxygen flow in order to have better burnout.

10- Supporting Documents

MSDS of Power Resins LCD Resin

11- Label Symbols